Gray Cast Iron Pipe

English

English

![]()

English

English

Russian

Russian

French

French

Spanish

Spanish

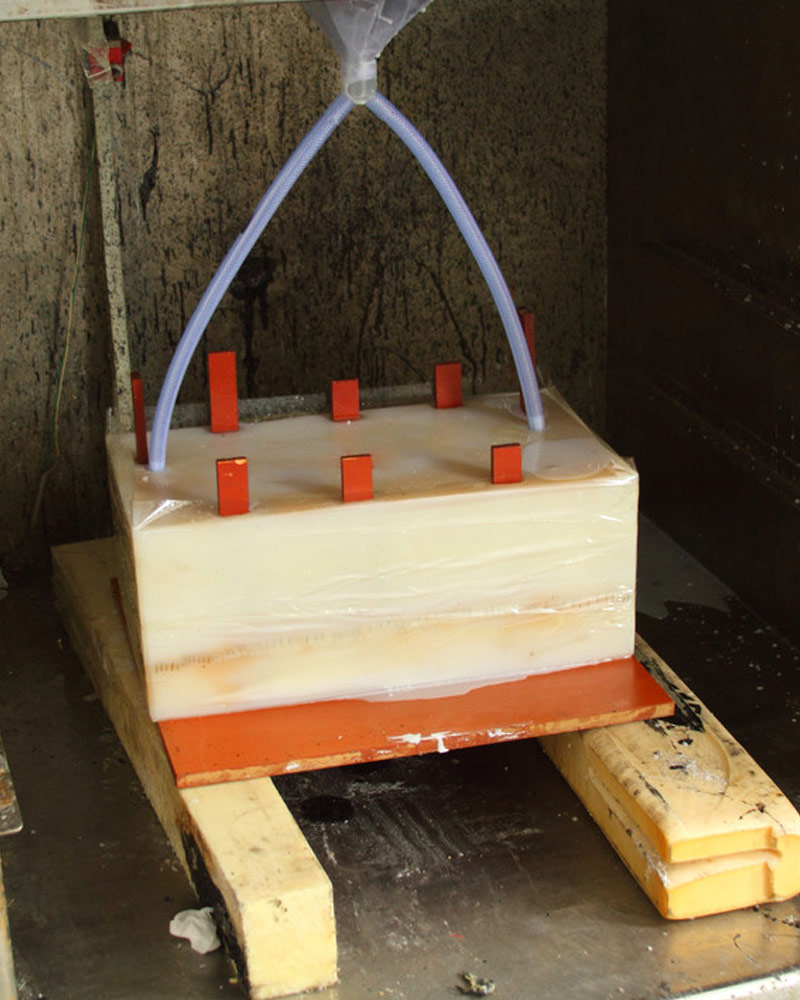

Vacuum casting can be roughly divided into three types: vacuum suction casting, vacuum low pressure casting, and vacuum differential pressure casting:

1. Vacuum suction casting

Place the casting mold in a closed container, and draw out the air in the casting mold to create a certain negative pressure in the casting mold, causing the molten metal to be sucked into the mold cavity. When the inner runner of the casting is solidified, the negative pressure is removed, so that the unsolidified metal liquid in the vertical runner flows back into the molten pool. The advantage is that the filling ability of the alloy liquid is improved, the minimum wall thickness of the suction casting casting can reach 0.2mm, and the casting area is 300mm2, and the defects such as pores and slag inclusions are reduced at the same time. It is suitable for the production of thin and fine small precision castings, especially cast steel (including stainless steel) parts.

2. Vacuum low pressure casting

The vacuum low pressure casting method is to vacuumize the casting mold during the process of pressurizing and filling. After the filling, the pressure is maintained to make the casting crystallize and solidify under a constant pressure, and the casting is fully fed, so the structure of the casting is dense and the mechanical properties are improved. This method is mostly used for precision casting of Al, Mg alloy castings

3. Vacuum differential pressure casting

Vacuum differential pressure casting is mainly to seal the resistance holding furnace and the casting mold, and pass compressed air with a high pressure such as 500kPa into the sealing cover. At this time, since the pressure inside the casting mold and the crucible is equal, the molten metal will not rise. , and then add 50kPa pressure on the metal liquid surface, the metal liquid will rise to fill the mold cavity. It is especially suitable for the production of complex thin-walled castings, but the equipment is large and the operation is troublesome. It is only used when there are special requirements.

Die durch das Gießverfahren hergestellten Gussteile sind von guter Qualität, glatter Oberfläche, klarer Kontur, genauer Größe und gleichmäßiger Härte, was die Lebensdauer der Gussteile effektiv verlängert.Sie werden von Benutzern gelobt und werden zum neuen Favoriten der Branche.

(1) Das Modell legt das Modell auf eine hohle Formplatte, und es gibt eine große Anzahl von Belüftungslöchern auf dem Modell.Wenn das Vakuum wirkt, helfen diese Löcher, dass die Kunststofffolie an dem Modell haftet.

(2) Filmheizung

Die Kunststofffolie mit hoher Dehnungsrate und hoher plastischer Verformungsrate wird mit einem Heizgerät erhitzt und erweicht. Die Erwärmungstemperatur beträgt im Allgemeinen 80 bis 120°C.

(3) Filmbildung

Bedecken Sie den erweichten Film auf der Oberfläche des Musters, führen Sie ihn durch die Luftlöcher und lassen Sie den Film unter einer Vakuumansaugung von 200–400 mmHg an der Oberfläche des Musters haften.

(4) Sandkasten aufstellen

Nachdem die Farbe aufgesprüht und getrocknet ist (es ist im Prozess nicht notwendig), wird der spezielle Sandkasten auf das mit der Folie bedeckte Modell gestellt.

(5) Schleifen und vibrieren

Fügen Sie trockenen Sand mit guter Fülleffizienz und einer Partikelgröße von 100-200 Mesh in den Sandkasten ein und führen Sie dann Mikrovibrationen durch, um den Sand auf eine höhere Dichte zu verdichten.

(6) Abdeckform

Öffnen Sie den Angussbecher, kratzen Sie die Oberfläche der Sandschicht ab und decken Sie ihn mit Plastikfolie ab, um den Sandkasten zu schließen.

(7) Schimmelentfernung

Der Kolben wird mittels einer die Oberfläche des Kolbens bedeckenden Folie evakuiert, um die Form unter Einwirkung von atmosphärischem Druck auszuhärten. Wenn die Form angehoben wird, wird das Vakuum der Unterdruckbox aufgehoben, um die Adsorptionskraft der Schablone auf der Folie freizugeben, und dann wird die obere Box angehoben, um die Form fertigzustellen.

(8) Gießen in geschlossene Box

Vor dem Schließen des Kastens können Kern und Kalteisen entsprechend den Prozessanforderungen abgesenkt und Ober- und Unterkasten zu einer Gießform mit Gießsteigrohr und Kavität kombiniert werden, die im Vakuum gegossen wird.

(9) Sand aus der Kiste

Nach entsprechender Abkühlzeit wird das Vakuum aufgehoben und der Normaldruck wiederhergestellt, so dass der fließfähige Sand ausfließt und ein sauberer Guss ohne Sandklumpen und mechanischen Sand erhalten bleibt. Der Sand kann nach dem Abkühlen wiederverwendet werden.

As far back as 1643, Italian physicist Torricelli discovered that there is atmosphere and atmospheric pressure in vacuum and natural space.

In 1650, Otto von Glick made a piston vacuum pump in Germany. In 1654, he conducted the famous Magdeburg hemisphere experiment in Magdeburg: this famous experiment once again proved that there is an atmosphere in space, and the atmosphere has a huge pressure

In the middle and late 19th century, the success of the British Industrial Revolution promoted the development of productivity and scientific experiments, as well as the development of vacuum technology. The use of compression vacuum gauges made it possible for the first time to measure low pressures.

At the beginning of the 20th century, the appearance of vacuum tubes promoted the development of vacuum technology to high vacuum. From 1935 to 1937, the gas ballast vacuum pump, oil diffusion pump and cold cathode ionization meter were invented. These results and the Pirani gauge made in 1906 are still used in most vacuum systems today.

After 1940, vacuum applications were expanded to nuclear research (cyclotron and isotope separation, etc.), vacuum metallurgy, vacuum coating and freeze drying, etc., vacuum technology began to become an independent discipline. During the Second World War, the need for atomic physics experiments and the need for high-quality electrical vacuum devices for communication further promoted the development of vacuum technology.

Vacuum casting can be roughly divided into three types: vacuum suction casting, vacuum low pressure casting, and vacuum differential pressure casting:

1. Vacuum suction casting

(1) Vacuum suction casting is conducive to the removal of gas in the mold, suppressing the generation of turbulent flow and entrainment, overcoming the disadvantages of low-pressure casting and differential pressure casting, and significantly improving the filling ability of molten metal.

(2) Due to the improvement of mold filling ability during vacuum suction casting, the casting temperature of molten metal can be 20~30 °C lower than that of gravity casting.

(3) Castings with large difference in wall thickness, thin wall and high quality requirements can be cast.

(4) By selecting an appropriate vacuum degree change rate and controlling the speed of the molten metal entering the mold cavity, a stable filling effect can be obtained.

2. Vacuum low pressure casting. Its advantages are as follows:

(1) The existence of vacuum negative pressure can make the molding sand compact and increase the strength of the casting mold.

(2) Appropriately increase the degree of vacuum, so that the filling time is shortened, and the filling speed is not only accelerated but also stable.

(3) Vacuum low pressure casting can speed up the fluidity of aluminum alloy at low temperature, avoid the phenomenon of inhalation of aluminum alloy cast at high temperature, and increase the pinhole defect of the casting.

(4) The casting has good formability, which is conducive to the formation of castings with clear outlines and smooth surfaces and large thin-walled castings.

(5) The structure of the casting is dense and the mechanical properties are high.

(6) Under normal circumstances, no riser is needed, which greatly improves the yield of molten metal, usually up to 90%.

(7) The working environment is good and the equipment is simple, which is helpful for mechanization and automation.

3. Vacuum differential pressure casting. Its advantages are as follows:

(1) Compared with traditional gravity casting and vacuum suction casting, vacuum differential pressure casting shows a good filling ability on 1mm thick sheet samples.

(2) The casting has a denser crystalline structure and mechanical properties. The strength of the casting is about 20%~25% higher than that of vacuum suction casting and gravity casting, and the elongation is about 50% higher.

(3) Vacuum die casting can effectively reduce the pores of die castings and increase the density of castings by more than 1%.

We provide our customers with a full range of products, services and solutions to help them remain competitive in their respective fields. We handle every job with the best process for lowest cost, best quality and highest efficiency. Our capabilities are comprehensive and include engineering design, sample development, process control, heat treatment, machining, inspection, and shipping and delivery. Thanks to our extensive experience and expertise in casting and machining, we are able to produce a wide range of parts and assemblies serving a wide range of industries and applications.

We attach great importance to quality. We are ISO9001/2015, AS9100 ISO45001:2018 and PED 97/23/E, ADW0 and API 6D certified by BV, TUV and DNV. The implementation of the ISO9001 quality management system ensures the good performance of our products and services, enabling us to establish long-term business relationships with customers all over the world.

Vacuum casting is an incredibly useful industrial process for creating plastic prototypes and products quickly and effectively. Using a vacuum ensures that no air bubbles are present in the finished product, allowing designers to guarantee their products have a high quality finish. In addition, due to the fast nature of the processing, fewer mistakes are made and changes can be implemented with much greater ease.

Vacuum casting is an affordable solution to create multiple customised parts which allows businesses to save money and resources while still producing high-quality designs. It's no wonder it is a preferred method used across many diverse industries today.

The field is required.

The field is required.

The field is required.

The field is required.

Send