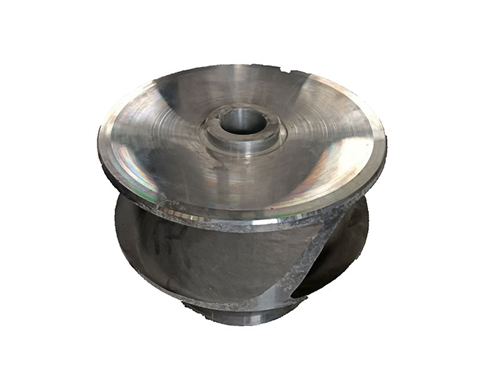

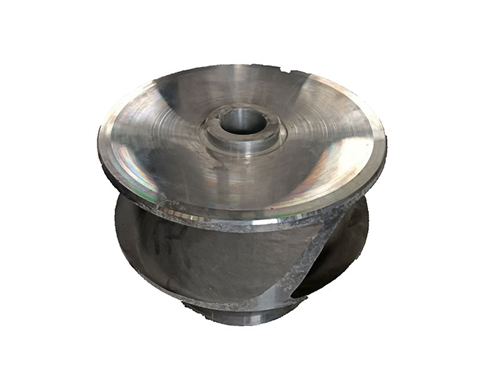

Water pump impellers play a pivotal role in ensuring the smooth and efficient operation of various pumping systems. These intricate components come in different materials and craftsmanship, with CD4MCU, CA6NM, and white iron being prominent choices for their construction through sand casting or lost foam techniques. In this comprehensive exploration, we will delve into the multifaceted advantages of water pump impellers, shedding light on how they contribute to enhanced performance and reliability across diverse applications.

Understanding Water Pump Impellers

Water pump impellers are crucial components within pump systems, responsible for generating the fluid flow necessary for various industrial and domestic applications. Their design and material choices significantly impact the overall efficiency and longevity of the pumping system. Let's delve into the distinct advantages associated with water pump impellers.

Superior Material Choices: CD4MCU, CA6NM, White Iron

The selection of materials for water pump impellers is a critical factor influencing their performance and durability. Manufacturers often opt for materials such as CD4MCU, CA6NM, and white iron due to their exceptional properties.

CD4MCU: Corrosion Resistance Unleashed

CD4MCU, a duplex stainless steel, stands out for its remarkable corrosion resistance. This feature makes it an ideal choice for water pump impellers, especially in applications where exposure to corrosive environments is a concern. The impellers crafted from CD4MCU ensure a longer lifespan and reduced maintenance costs.

CA6NM: Combating Abrasion with High Strength

When abrasion resistance is a priority, CA6NM, a type of martensitic stainless steel, steps into the spotlight. The inherent strength of CA6NM makes it a preferred material for water pump impellers operating in conditions where abrasive particles are present. This durability translates to extended service life and heightened reliability.

White Iron: Hardness Redefined

In applications demanding exceptional hardness, white iron emerges as a go-to material for water pump impellers. Its high level of hardness makes it particularly suitable for handling abrasive media, ensuring that the impeller maintains its structural integrity even in challenging environments.

Craftsmanship Matters: Sand Casting and Lost Foam Techniques

Apart from material selection, the craftsmanship employed in creating water pump impellers plays a pivotal role in determining their effectiveness. Two prevalent techniques in this regard are sand casting and lost foam.

Sand Casting: Precision in Every Grain

Sand casting is a traditional yet highly effective method for crafting water pump impellers. This process involves creating a mold from sand and pouring molten metal into it, resulting in a precise and detailed impeller. Sand casting allows for intricate designs, ensuring that the impeller functions with optimal efficiency.

Lost Foam: Molding Complexity

Lost foam casting is a modern and versatile technique that offers advantages in terms of complexity and design flexibility. In this method, a foam pattern of the impeller is created and surrounded by a casting flask. Molten metal is then poured over the foam, causing it to vaporize and leaving behind a meticulously shaped impeller. Lost foam casting is particularly beneficial when intricate designs or complex geometries are required for optimal pump performance.

Unveiling the Advantages

With a solid understanding of the materials and craftsmanship involved, let's explore the specific advantages that water pump impellers bring to the table.

Efficiency Beyond Measure

Water pump impellers are designed to maximize efficiency in fluid transfer, ensuring that every rotation translates into effective pumping action. The combination of well-chosen materials and precise craftsmanship minimizes energy losses, resulting in pumps that operate at peak efficiency levels.

Corrosion Resistance: CD4MCU's Triumph

The utilization of CD4MCU in water pump impellers provides a formidable defense against corrosion. Whether the application involves water with high chloride content or other corrosive elements, impellers crafted from CD4MCU remain resilient, maintaining their structural integrity over extended periods.

Robust Against Abrasion: CA6NM's Fortitude

In scenarios where abrasive particles pose a threat to pump components, impellers made from CA6NM shine. The high strength of CA6NM ensures that the impeller can withstand the abrasive forces, preventing premature wear and tear. This robustness translates into a longer lifespan for the pump system.

Hardness Redefined: White Iron's Endurance

The superior hardness of white iron makes impellers crafted from this material well-suited for applications involving abrasive media. Whether it's handling gravel or other abrasive substances, water pump impellers made from white iron exhibit unparalleled endurance, contributing to the overall reliability of the pump system.

Precision in Design: Sand Casting's Legacy

The traditional method of sand casting contributes to the precision and reliability of water pump impellers. The detailed molds created through sand casting ensure that the impellers maintain their intended design, allowing for seamless integration into diverse pump systems. This precision is crucial for achieving optimal performance.

Complexity with Versatility: Lost Foam's Innovation

Lost foam casting introduces a level of versatility and complexity to water pump impeller design. This innovative technique allows for the creation of intricate geometries that might be challenging or impossible with other manufacturing methods. The result is impellers that can adapt to specific pumping requirements with unparalleled efficiency.

Applications of Water Pump Impellers

Water pump impellers find application across various industries, each benefiting from their unique advantages. Let's explore some key sectors where these impellers play a crucial role.

Industrial Pumping Systems: Powering Productivity

In industrial settings, water pump impellers are integral components of pumping systems that transfer liquids for various processes. Whether it's handling chemicals, cooling fluids, or other industrial liquids, the efficiency and durability of the impeller directly impact overall productivity.

Municipal Water Treatment: Ensuring Clean Water Supply

Municipalities rely on water pump impellers to ensure the efficient transfer of water within treatment plants. The corrosion resistance of materials like CD4MCU becomes particularly valuable in this context, where exposure to different water qualities is inevitable.

Agriculture Irrigation: Nurturing Crops with Precision

Agricultural irrigation systems depend on water pump impellers for the precise distribution of water to crops. The robustness of impellers made from CA6NM proves crucial in handling water containing soil particles, contributing to the longevity of irrigation systems.

Mining Operations: Tackling Abrasive Challenges

Mining operations often involve the handling of abrasive slurries, making water pump impellers a critical component in the pumping systems. Impellers crafted from white iron excel in these environments, providing the necessary hardness to withstand abrasive forces.

HVAC Systems: Regulating Climate Comfort

Heating, ventilation, and air conditioning (HVAC) systems rely on water pump impellers for the circulation of cooling or heating fluids. The efficiency and precision of impellers contribute to the overall effectiveness of HVAC systems in maintaining optimal climate conditions.

Conclusion

Water pump impellers stand as silent champions in the realm of fluid transfer systems. Their advantages, rooted in material science and manufacturing craftsmanship, translate into enhanced efficiency, durability, and versatility. Whether it's combating corrosion, resisting abrasion, or facilitating complex designs, water pump impellers play a crucial role in diverse applications across industries.

As technology advances and the demand for more efficient and reliable pumping solutions continues to rise, the role of water pump impellers will only become more pronounced. Their ability to withstand the challenges posed by different environments and substances positions them as indispensable components in the machinery that drives progress across various sectors. In the ever-evolving landscape

English

English

![]()

English

English

Russian

Russian

French

French

Spanish

Spanish