What is an Impeller?

An impeller is a rotating component that imparts motion and energy to fluids. It consists of curved blades or vanes arranged in a specific pattern around a central hub. When the impeller rotates, it generates kinetic energy and creates a pressure gradient, causing the fluid to move or be transferred.

Types of Impellers

There are various types of impellers, each designed to suit specific applications and fluid dynamics. Some common types include:

Radial Flow Impellers: These impellers move fluid primarily in a radial direction, perpendicular to the impeller's rotation axis.

Axial Flow Impellers: Axial flow impellers move fluid parallel to the impeller's rotation axis, creating a more axial or linear flow pattern.

Mixed Flow Impellers: Mixed flow impellers combine radial and axial flow characteristics, providing a combination of radial and axial thrust.

Impeller Design

Key Design Considerations

When designing an impeller, several factors must be taken into account. These include:

Flow Rate and Pressure Requirements: The impeller design should accommodate the desired flow rate and pressure characteristics of the fluid system.

Fluid Properties: Different fluids have unique characteristics that influence impeller design, such as viscosity, density, and temperature.

Operating Conditions: The operating environment, including temperature, pressure, and corrosive factors, must be considered during impeller design.

Impeller Geometry

Impeller geometry plays a vital role in its performance. The shape, size, and curvature of the blades determine the flow pattern and efficiency. Some common impeller geometries include:

Forward-Curved Blades: These blades curve in the direction of rotation, suitable for low-pressure applications.

Backward-Curved Blades: Blades that curve against the direction of rotation, commonly used in high-pressure applications.

Radial Blades: Radial blades extend straight out from the impeller hub, providing a balanced flow pattern.

Materials Used

Impellers are typically constructed using materials that offer a combination of strength, corrosion resistance, and durability. Common materials include stainless steel, bronze, aluminum, and various composite materials. The choice of material depends on factors such as fluid properties, operating conditions, and budget considerations.

Impeller Applications

Pump Impellers

Pump impellers are widely used in industries such as water management, oil and gas, and manufacturing. They are responsible for transferring fluids from one location to another by generating sufficient pressure and flow. Pump impellers vary in design and size, depending on the specific pumping requirements.

Turbine Impellers

Turbine impellers are crucial components in turbines, converting fluid energy into mechanical energy. They are commonly found in hydroelectric power plants, steam turbines, and jet engines. Turbine impellers are designed to efficiently harness the kinetic energy of the fluid, driving the rotation of the turbine blades.

Compressor Impellers

Compressor impellers are employed in gas compression systems, such as air compressors and refrigeration units. These impellers draw in the gas or air, compress it, and then discharge it at a higher pressure. Compressor impellers play a vital role in maintaining optimal system performance and energy efficiency.

Fluid Dynamics and Impeller Performance

Flow Characteristics

Impeller design significantly influences the flow characteristics of the fluid within a system. The impeller's shape, blade angles, and rotational speed determine the flow pattern, including laminar or turbulent flow. The efficiency of the impeller relies on creating an optimal flow pattern that minimizes energy losses and maximizes fluid transfer.

Impeller Efficiency

Impeller efficiency refers to the ability of the impeller to convert mechanical power into fluid energy with minimal losses. Efficient impeller design ensures higher energy transfer, resulting in improved system performance and reduced energy consumption. Factors such as impeller geometry, blade profile, and rotational speed affect the overall efficiency.

Cavitation and Impeller Damage

Cavitation occurs when the pressure within a fluid system drops below the vapor pressure, forming vapor bubbles. These bubbles implode near the impeller blades, leading to erosion, pitting, and damage. Proper impeller design and system maintenance are crucial to mitigate cavitation and prevent impeller failure.

Maintenance and Troubleshooting

Impeller Maintenance

Regular maintenance is essential to ensure the longevity and optimal performance of impellers. Some key maintenance practices include:

Cleaning: Removing debris and deposits from the impeller surface and blades.

Inspection: Checking for signs of wear, damage, or erosion.

Balancing: Ensuring the impeller is properly balanced to prevent excessive vibration.

Common Impeller Issues

Several issues can arise with impellers, such as:

Wear and Erosion: Impeller blades may wear out over time due to fluid abrasion, leading to reduced efficiency.

Corrosion: Corrosive fluids can cause damage to the impeller material, compromising its structural integrity.

Misalignment: Improper alignment of the impeller within the system can result in performance issues and increased wear.

Troubleshooting Tips

When encountering impeller-related problems, consider the following troubleshooting tips:

Check for blockages or obstructions in the fluid system.

Verify the impeller rotation direction and ensure it matches the system requirements.

Inspect seals and gaskets for leaks that may affect impeller performance.

Future Developments and Innovations

Advanced Impeller Designs

Researchers and engineers are continuously exploring advanced impeller designs to enhance efficiency and performance. Some developments include optimized blade profiles, improved materials, and computer-aided design techniques.

Computational Fluid Dynamics (CFD)

CFD simulations are playing an increasingly significant role in impeller design and analysis. By using computational models and fluid dynamics simulations, engineers can evaluate impeller performance, optimize designs, and predict flow characteristics with greater accuracy.

Where to buy valve impellers?

Authorized by the National Department of Foreign Economic Relations and Trade, Shijiazhuang Jinjieber Imp.& Exp. Co. Ltd specializes in hardware, construction materials, steel, light industrial and chemical products, machinery, and electronic equipment.

Water Pump Impeller Parts CA6NM

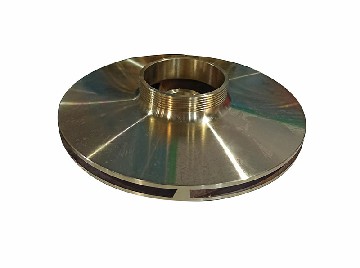

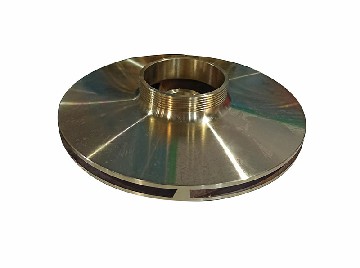

Brass Impeller Water Pump Parts

High Hardness Impeller CA6NM 450-500BHN

English

English

![]()

English

English

Russian

Russian

French

French

Spanish

Spanish